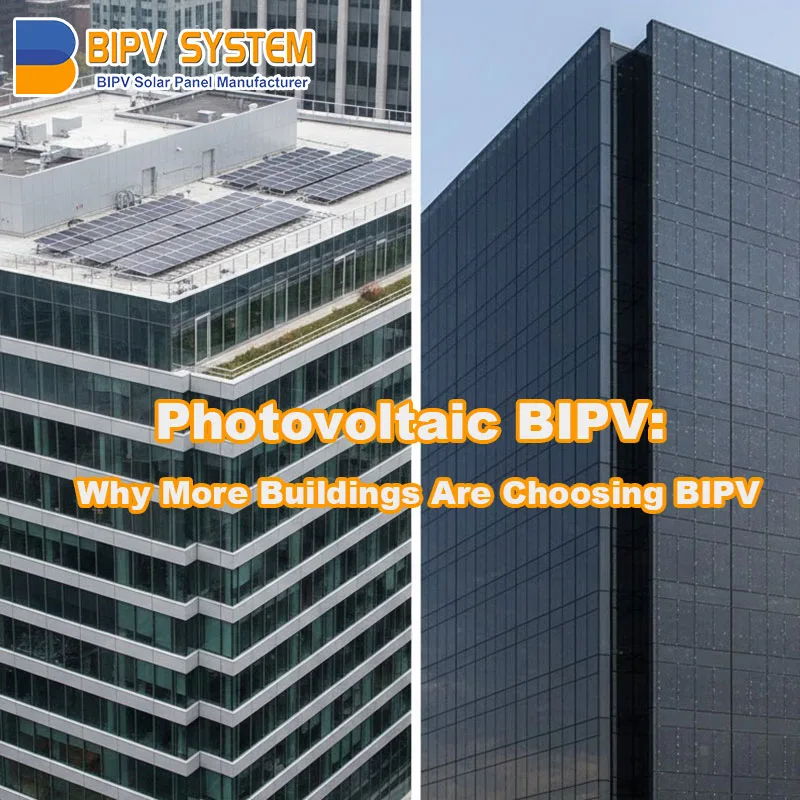

In the global push for Net Zero Energy Buildings (NZEB), BIPV (Building-Integrated Photovoltaics) is redefining the building “skin.” It is no longer just about slapping solar panels onto a roof; it is about transforming the building itself into a power station.

But from a technical perspective, how does BIPV work? Where do the wires go? How does it protect against rain and heat while generating electricity? This article takes you deep into the mechanics of BIPV work principle.

Table of Contents

Overall composition of BIPV photovoltaic power generation

BIPV system mainly consists of two parts: BIPV photovoltaic modules and System balance (BOS) module.

BIPV modules are the actual sites where sunlight is converted into electricity. High-energy photons in sunlight excite electrons in semiconductor materials, causing them to transition to higher energy conduction bands. These electrons can then move freely in external circuits, generating an electric current. The electricity generated by photovoltaic modules is always direct current (DC).

The Balance of System (BOS) module encompasses all components other than the photovoltaic modules, including: wiring, combiner boxes, DC and AC circuit breakers; inverters; switchboards; and batteries. (This article focuses on How BIPV Work, so we will discuss the Balance of System (BOS) module in subsequent articles.)

Key Takeaways: BIPV Work Principle

BIPV (Building-Integrated Photovoltaics) is a technology where solar power generation products are seamlessly integrated into the building envelope—serving as the roof, windows, or facade. The BIPV work principle can be summarized in three core steps:

Absorption & Conversion: Photovoltaic cells (PV Cells) embedded within the glass or tiles absorb solar photons and convert them into direct current (DC) electricity via the photovoltaic effect.

Hidden Transmission: The generated current travels through specialized wiring hidden within the building framework (such as curtain wall mullions or window frames), maintaining an invisible aesthetic.

Inversion & Connection: An inverter converts the DC electricity into alternating current (AC), which is then used directly by the building or fed back into the electrical grid.

The Physical Layer: More Than Just Power, It’s Construction Material

Unlike traditional BAPV (Building-Attached PV), a BIPV module must first and foremost be a compliant construction material.

Most BIPV modules (especially PV glass) utilize a structure similar to laminated safety glass(The “Sandwich” Structure)

Front

Front Glass: Ultra-clear tempered glass designed for high light transmission and impact resistance.

The PV Layer (Interlayer)

Crystalline Silicon: High efficiency, usually appearing as black squares. Transparency is achieved by adjusting the spacing between cells.

Thin-Film (CdTe/CIGS): A uniform power-generating film deposited on the glass. It offers customizable colors and superior performance in low-light conditions.

Back

Back Glass/Backsheet: Provides structural support and physical protection.

The Electrical Layer: The Art of Hidden Wiring

This is often the most challenging aspect for engineers and the key differentiator of BIPV. While standard solar panels have visible conduits, BIPV must be “invisible.”

Edge Connectors: BIPV modules typically avoid the bulky junction boxes found on standard panels. Instead, they use ultra-slim edge connectors or miniaturized junction boxes (often <15mm thick) that can be perfectly concealed within the metal frame of the curtain wall.

Wiring in Mullions: In photovoltaic curtain wall systems, cables are routed through the hollow chambers of the aluminum mullions and transoms. This not only preserves the aesthetic appeal but also protects the wiring from wind and rain.

Back Contact Technology (IBC): For the ultimate aesthetic, high-end BIPV uses Interdigitated Back Contact (IBC) cells. All the metal busbars are moved to the back of the cell, leaving the front face a pure, uniform glass surface with no visible silver lines.

Thermal Management: The Ventilated Facade

Solar cells have a unique characteristic: the hotter they get, the less efficient they become. Since BIPV acts as the wall itself, how is heat managed?

Double-Skin Facade: This is the most effective thermal solution for BIPV. An air gap (usually 10-20cm) is left between the BIPV module and the inner wall.

The Chimney Effect: Heated air rises and vents out the top, while cool air is drawn in from the bottom. This natural convection cools the solar cells (boosting efficiency) and acts as an insulation layer, significantly reducing the building’s indoor air conditioning load.

System Architecture: From Roof to Grid

| Component | Function |

|---|---|

| Micro-inverters / Optimizers | Critical for BIPV. Since building surfaces have different orientations and shading issues (e.g., shadows from trees), traditional string inverters can suffer from the "weakest link" effect. Micro-inverters control each module independently, ensuring one shaded window doesn't stop the whole wall from generating power. |

| Combiner Box | Consolidates multiple DC inputs, usually installed in a utility room or ceiling space. |

| Bi-directional Meter (Net Metering) | If the building generates more power than it needs, the meter "spins backward," selling the excess energy to the grid for credit. |

FAQ on How Does BIPV work principle

Will BIPV affect indoor natural lighting?

It is controllable. By adjusting the density of crystalline cells or using laser-etched thin-film layers, BIPV glass transparency can be customized between 10% and 60%. It acts as “smart shading,” filtering out harsh glare while allowing soft natural light to enter.

What is the lifespan of BIPV system?

Standard BIPV modules are designed with a lifespan of 25 to 30 years, matching the durability of high-performance architectural glass. Electrical components (like inverters) may require maintenance or replacement after 10–15 years.

Does BIPV work on cloudy days?

Yes. While output decreases compared to sunny days, PV systems rely on solar radiation, not just direct heat. Thin-film BIPV, in particular, performs exceptionally well in diffuse light conditions (cloudy days, early mornings, or late afternoons).

Conclusion

The working principle of BIPV is not just about the physics of “photoelectric conversion”; it is a sophisticated integration of architecture, electrical engineering, and material science. It empowers every building with the potential to become an independent micro-energy hub.

Wondering which BIPV solution fits your project? [Contact our energy experts for a free assessment]