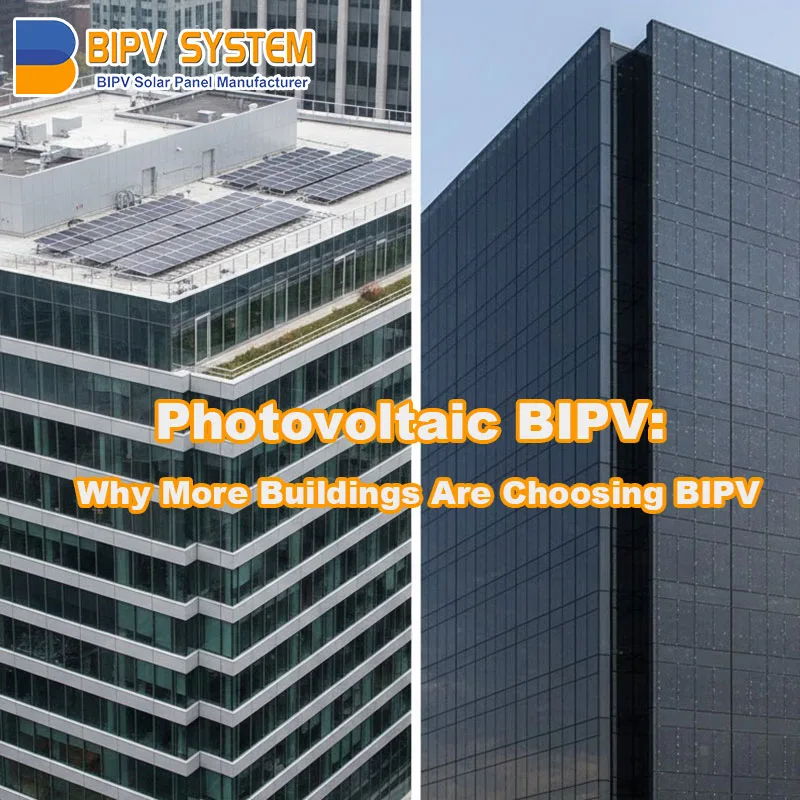

Photovoltaic BIPV (building-integrated photovoltaics) means PV materials are integrated into the building envelope—roof, façade, skylights, canopies, or shading—so they replace conventional building materials while generating electricity. In normal words: the building “skin” does two jobs—weather protection + power production—instead of being a passive surface. This “replace, not add” idea is the defining difference from typical rooftop solar.

I remember a conversation I had with a developer in 2021 who was terrified of the “extra cost” of solar glass. Fast forward to 2026, and that same developer won’t even look at a blueprint unless it includes photovoltaic bipv. Why the change? It wasn’t just about “saving the planet”—it was about the realization that a building’s skin shouldn’t just be an expense; it should be an asset.

That’s where BIPV buildings stop being a fancy concept and start becoming a practical answer.

The featured-snippet answer

BIPV buildings help achieve green building goals by reducing operational carbon through on-site renewable electricity, while meeting envelope functions (cladding, glazing, shading). They support net-zero pathways that prioritize energy efficiency first and then supply remaining demand with renewable energy, and they align with certification frameworks that recognize on-site/near-site renewables and metered performance.

Table of Contents

Why green building targets increasingly “pull” BIPV into the conversation

This is the uncomfortable truth: the building sector is big enough that small optimizations won’t get us there.

The GlobalABC/UNEP Global Status Report notes that in 2022, buildings were responsible for 34% of global energy demand and 37% of energy and process-related CO₂ emissions.

The IEA similarly highlights that building operations account for about 30% of global final energy consumption and 26% of global energy-related emissions (split across direct and indirect).

The IPCC AR6 (WGIII) discusses the split between operational and embodied emissions in buildings, underscoring why both matter in decarbonisation strategies.

So green building goals (LEED, BREEAM, net-zero programs, local codes) are increasingly pushing projects toward measured energy performance and renewable supply—not just “nice materials.”

What “Photovoltaic BIPV” really means

IEA PVPS Task 15 puts it clearly: a BIPV module is both a PV module and a construction product, designed to be a component of the building; if you remove it, you must replace it with another construction product.

That definition is more than semantics. It changes who needs to be in the room:

Architect / facade consultant: appearance, module layout, daylight, glare

Structural engineer: wind loads, anchors, facade substructure

MEP engineer: string design, inverters, protection, monitoring

GC / facade contractor: tolerances, waterproofing, installation workflow

Owner / facility team: access, cleaning, replacement strategy

If Photovoltaic BIPV is treated as “just solar,” it tends to get value-engineered away. If it’s treated as a building system with electrical output, it survives procurement much more often.

How BIPV buildings map to green building goals

1. Net-zero and near-net-zero pathways

WorldGBC’s net-zero guidance emphasizes a “golden rule”: reduce energy demand first, then supply remaining demand with renewables (on-site and/or off-site depending on feasibility).

Photovoltaic BIPV supports that second part—renewable supply—especially where roofs are limited (dense cities, high-rise, equipment-heavy roofs).

2. LEED and renewable energy recognition

USGBC’s LEED v4.1 credit language around Renewable Energy explicitly recognizes on-site renewable energy systems (and/or off-site procurement) tied to annual building energy use.

Photovoltaic BIPV is often one of the cleanest ways to make “on-site renewables” real without sacrificing roof real estate.

3. BREEAM and renewables

BREEAM discusses how its assessments recognize and reward on-site/near-site renewables and account for carbon reductions (including exported renewable electricity).

Again, the practical issue is surface area: façades and canopies are simply underused “solar real estate” in many projects.

Case studies: what BIPV buildings look like when they’re done properly

I’ll give you the “engineer’s view” first, then we’ll translate it into integration methods.

Case A: Copenhagen International School (Denmark) — facade PV at architectural scale

This project is famous because it made a bold statement: a large facade covered with solar “tiles” can be both aesthetic and productive. Multiple architecture publications describe the building’s facade as being covered with 12,000 solar panels/tiles and cite production figures around hundreds of MWh per year, covering a substantial share of demand.

A technical case document in an international BIPV collection describes the facade integration approach and scale (thousands of square meters of PV facade).

Why it matters for green building goals:

It demonstrates that “on-site renewables” can move beyond roofs.

It treats PV as a façade material (buildable, repeatable, maintainable).

It reframes the conversation from “add solar” to “design the envelope as an energy asset.”

Case B: CIS Tower (Manchester, UK) — retrofit PV cladding on an existing high-rise

For existing buildings chasing carbon reduction, the biggest pain is usually the envelope: you’re recladding anyway, so why not make the new skin generate power?

The CIS Tower recladding effort is documented in official/public materials, including EU-level project documentation about the recladding measure.

IEA PVPS reporting has also referenced the CIS Tower PV façade as a notable large façade system in the UK context.

Why it matters for green building goals:

It’s a real-world example of decarbonising an existing asset via envelope retrofit.

It shows a path where the “green upgrade” isn’t only HVAC—it’s the facade itself.

It’s the kind of project that convinces owners: we can renew the building and cut operational carbon together.

Why it matters:

This is the bridge between glossy architecture and engineering reality: detailing, interfaces, performance monitoring, and procurement lessons—exactly what green building teams need when they move from target-setting to delivery.

BIPV vs BAPV for green buildings

Here’s the honest framing I use.

BAPV tends to win on:

Simplicity and cost efficiency per installed watt

Easy access for maintenance

Standardised components and installation workflows

BIPV buildings tend to win when:

Roof area is too small or too shaded to matter

The project already requires facade elements like sunshades, spandrels, canopies, skylights

Aesthetics and planning constraints matter (PV must look like a building product)

The owner values a single integrated scope: envelope + energy

And one subtle point: because Photovoltaic BIPV is a construction product, the “cost conversation” should be incremental cost vs the façade material it replaces, not “BIPV cost vs nothing.” The IEA PVPS definition basically forces that comparison.(Further reading: Why it matters: BIPV vs. BAPV for green buildings.)

Technical structure: what a BIPV system actually includes

Photovoltaic BIPV products (modules/tiles/glazing units) sized for facade grids

Mounting/substructure compatible with curtain wall or cladding systems

Waterproofing and drainage strategy (especially for canopies and skylights)

Electrical design: strings, DC protection, inverters, AC distribution

Monitoring: generation metering, fault detection, performance ratio tracking

Access and maintenance plan: cleaning, replacement, safe isolation

IEA PVPS emphasizes standardisation and practical guidance as key barriers/enablers for wider Photovoltaic BIPV adoption—so system-level thinking isn’t optional.

The “green building” checklist for BIPV buildings

If your search intent is “I need an answer, not a brochure,” these are the questions that decide success:

What surface are we integrating into (facade / roof / canopy / skylight)?

What is the primary envelope function (shading / weather barrier / daylight)?

How will we prevent thermal and moisture problems behind PV?

How will we maintain it (access, cleaning frequency, replacement approach)?

How will we measure performance (metering + monitoring)?

Which certification target are we supporting (LEED/BREEAM/net-zero policy)?

This last point is where EEAT becomes real: green building teams trust what can be specified, built, inspected, and measured.

How BIPVSYSTEM supports BIPV buildings

On BIPVSystem-style projects, the goal is usually not “sell a panel.” It’s to make Photovoltaic BIPV behave like a dependable envelope package:

Facade-grid-friendly module design (so architects and façade contractors can actually build it)

Application-driven integration: spandrel zones, sunshades, canopies, skylights—where Photovoltaic BIPV adds functional value

Engineering documentation: interface details, wiring routes, safe isolation points, and monitoring scope

Project realism: if a parameter isn’t fixed yet, we treat it as typical / common / customizable and define the decision conditions (orientation, shading, local code, desired appearance)

If you share your building type + envelope system (curtain wall/cladding/canopy), we can propose a concept layout that’s technically buildable and certification-aligned—so your green goal doesn’t die in value engineering.

FAQ (People Also Ask)

What are BIPV buildings?

BIPV buildings integrate photovoltaic modules into the building envelope so the PV replaces conventional materials (facade/roof/skylight/shading) while generating electricity—meaning the building “skin” is also part of the power system.

How do BIPV buildings help achieve net-zero goals?

Net-zero pathways prioritize reducing energy demand first, then meeting remaining demand with renewables. BIPV contributes on-site renewable generation using façade and envelope surfaces when roof area is limited.

Are BIPV buildings “better” than BAPV?

Not always. BAPV is often simpler and cheaper per watt. Photovoltaic BIPV becomes the better choice when roof space is limited, when PV can replace facade materials, or when the envelope needs shading/glazing solutions anyway—so BIPV delivers both building and energy functions.

What are the biggest technical risks in BIPV projects?

Common risks include wind-load detailing, waterproofing/drainage at envelope interfaces, thermal/moisture management behind modules, fire strategy and cable routing, glare/daylight considerations for glazing PV, and maintenance access. (These must be engineered like a façade system and an electrical system together.)

If you’re still reading, you’re probably past the “what is BIPV” stage—you’re trying to decide whether it can survive your project’s constraints.

Send me three things: building type, envelope system (curtain wall / cladding / canopy / skylight), and a rough orientation + shading situation. I can map a BIPV integration concept to your green building target (LEED/BREEAM/net-zero pathway) so the plan feels less like a slogan—and more like something you can actually build.